There are numerous shortcomings of traditional approaches to achieving Operational Excellence in the face of growing complexity. The 7 Element Operational Excellence Management System (OEMS) systematically addresses risk across an organization to achieve industry-leading results.

The next question is, "Where do I start?"

Trying to answer that question for the traditional approaches can be overwhelming; at least I found it to be. When I accepted my first role as the plant manager of a manufacturing facility, I did what most young and ambitious operations leaders do - I read every book I could find on Operational Excellence, Total Quality Management, Total Productive Maintenance, Toyota Production System, LEAN, Six Sigma, LEAN Six Sigma, etc.

After two weeks of reading, I found myself becoming more and more frustrated trying to figure out what I should do. It struck me that the first three quarters of each book discussed how great the prescribed approach was and why it was the right tool for the job. Along with the foundational explanations of the approach, these books were filled with stories of companies that followed their methodology and the dramatic performance improvements that resulted. Those stories really got me fired up and excited about the opportunity to make the same kind of impact in the plant I was about to be in charge of, but they left me wanting more. I wanted to know, tactically, where to start, how to get on the ground and what I should be doing on a daily basis. Unfortunately most of the books included only scant details on how to get started with implementation.

When there were explanations of where/how to get started, they were very brief and were short on specifics. And often times the first step was to stand up a new, special organization and train an army of disciples to go forth and implement the tools of the methodology – not something that could be done quickly, easily or with limited resources.

None of those books had what I (and I assume many other people) was looking for: a simple, repeatable system that can rapidly deliver improved performance. And for good reason, the traditional approaches don’t work that way. They don’t strip away complexity; they add complexity and perpetuate the Vicious Complexity Cycle by adding a plethora of new tools designed to solve discrete problems without taking the entire system in to account. In fact, they are so complex you have to progress through a rainbow of certifications to be considered competent to use them. Getting yourself in a position to design and lead an implementation is a massive personal undertaking.

In my time leading three different manufacturing facilities and advising countless others, I have found the 7 Element OEMS to be understood easily, implemented quickly and impactful across organizations. It is a simple, repeatable process that rapidly delivers results without creating a new bureaucracy or organization.

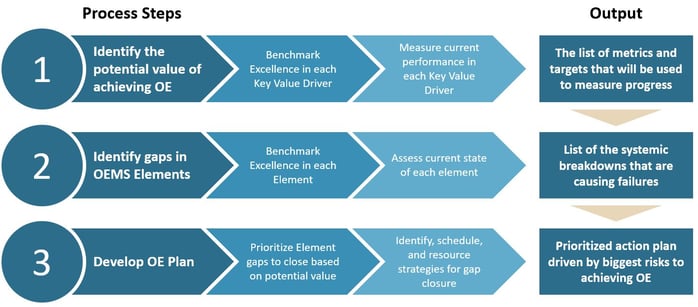

Whether you run a manufacturing plant, a complex make-to-order job shop, or even a service organization, implementation of the 7 Element OEMS follows the same path:

1. Determine the "size of the prize" - Determine your current performance in each of the 7 Value Drivers and compare that to industry benchmarks. This will tell you the potential value to be captured by achieving Operational Excellence.

2. Identify and prioritize gaps in the 7 Elements of the OEMS - Evaluate your current management system against best practices in each Element of the OEMS to identify gaps. Prioritize those gaps based on the potential to rapidly improve performance if they are eliminated.

3. Plan-Do-Check-Adjust (PDCA) - Apply the PDCA process to close the gaps.

If it seems simple and straightforward, that’s because it is. Over the next several articles, we will take a deeper look at each of the three steps, explaining them in more detail, and providing practical advice on how to rapidly, efficiently, and effectively execute them on your path to Operational Excellence.