- Expertise

- Private Equity Services

- Business Transformation

- Growth Strategy

- Technology Strategy

- Cost Reduction

- Customer & Product Profitability

- Product Portfolio Optimization

- Operating Model Redesign

- Operational Excellence

- Cybersecurity

- Management System

- Culture Measurement & Change

- Human & Org. Performance

- Commercial Excellence

- Insights

- Complexity

- Books

- Case Studies

- Cost reduction for a consumer durables co.

- Transforming go-to-market for a construction materials co.

- Organization sizing for a supply chain org.

- Proposal process overhaul for a global CRO.

- Revitalizing culture in the US Army

- Strategic capital deployment for global manufacturer

- Post-merger integration for a healthcare company

- Performance management in the US military

- Improving safety at a US refinery

- Leadership engagement at a manufacturer

- Workforce transformation toolkit: govt. org.

- Workforce transformation training: military

- Growth strategy for a steel fabricator

- Unlocking growth at a staffing services company

- Operating rules for a logistics org.

- Standardizing cost centers for a government organization

- Supply chain optimization for a Supply chain optimization for a U.S. government org.

- Optimizing production at a manufacturer

- Growth strategy for a major media company

- Growth opportunities for construction services

- Go-to-market strategy for a drilling co.

- Go-to-market strategy for a mining co.

- Growth strategy for a financial services org.

- Portfolio optimization at a European food company

- Client profitability for a sales and marketing company

- Complexity assessment at a powersports vehicle co

- Fast rollout for an integrated oil co.

- Transformation for a global energy company

- Changing portfolio management at a cosmetics company

- Finding portfolio opportunities at consumer durables co.

- Portfolio optimization at a bottler

- Portfolio reshaping at an industrial equipment co.

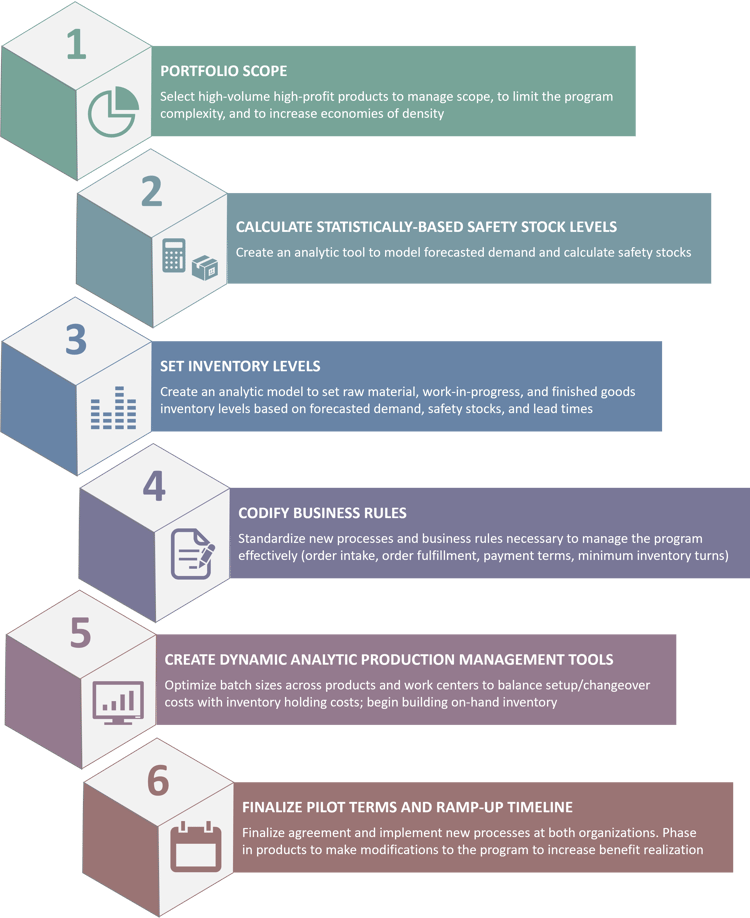

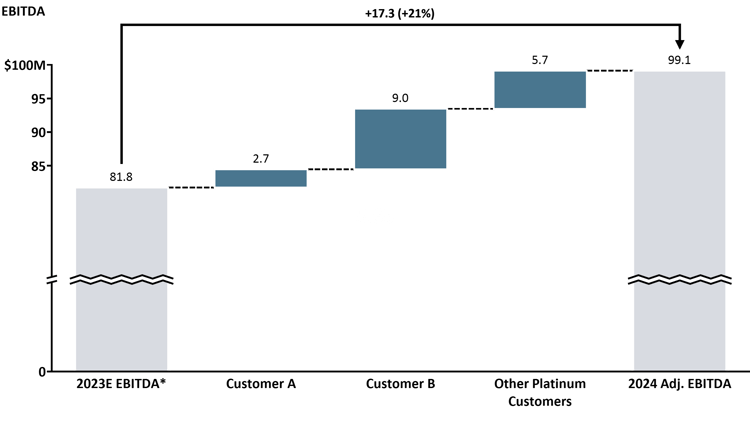

- Optimizing capital and capacity for a bottler

- Finance model transformation for a professional services co.

- Operating model redesign for a manufacturer

- Restructuring for growth at tech co.

- Working group effectiveness: logistics org.

- Employee assignments at a govt. org.

- Complexity costing for a major beverage company

- Drilling company reduces costs to regain profitability

- Battling proliferation at industrial equipment co.

- Technology strategy for a government supply chain org.

- Operational excellence at an ABA therapy provider

- Operating model redesign for a mental health provider

- Technology strategy for a staffing co.

- ERP modernization for the US Army

- Technology strategy for a financial institution

- Data management strategy for the US military

- Lowering costs for an environmental services company

- Cost reduction at a government organization

- Library

- Executive Webinars

- Latest Insights

- Yardstyck Culture Tool

- Global Markets Complexity Index

- Cybersecurity Complexity Report

- About

- Careers

- Contact

- Start the Conversation