The future operating model required realigning a workforce of over 1,500 generalist employees into functionally aligned roles and teams. The functionally aligned roles would continue to execute many of the existing supply chain activities, as well as newly designed and optimized processes. Since all job tasks were performed by generalists in the current state, the client was challenged with understanding the required resources to perform these tasks within a functionally aligned operating model. Furthermore, in practice the tasks performed varied widely across teams and the organization, so there was little understanding of resource requirements. Accurately allocating resources under the new model required a highly structured and data-driven approach.

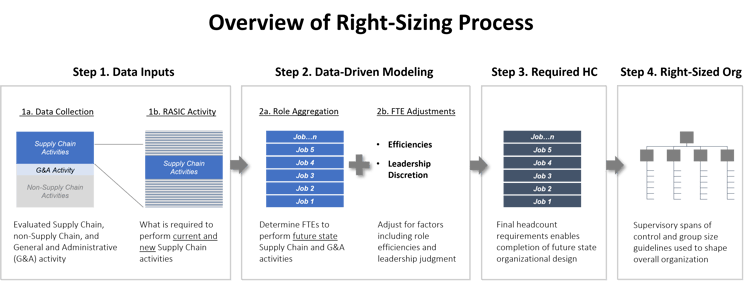

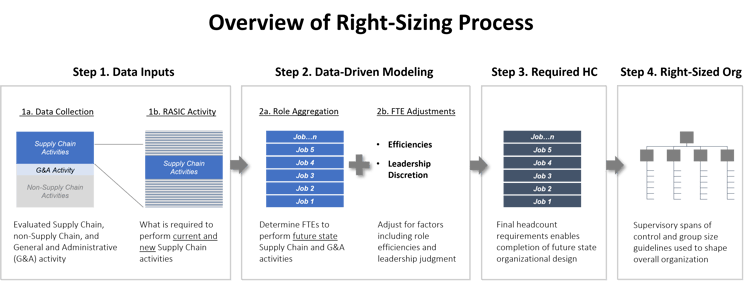

WP&C began by cataloguing and quantifying the full scope of work within the current generalist roles. WP&C developed a comprehensive inventory of all the processes, activities, and tasks performed and developed estimates for other ad hoc responsibilities that had to be performed by the generalists. This resulted in over 300 different activities being identified across the roles. WP&C then worked with leaders and employees throughout the organization to quantify the amount of time required to perform the various duties.

Next, the activities were mapped to the new standardized business processes and roles that were a part of the new operating model using a RASIC (Responsible, Accountable, Support, Inform, Consult) framework. The mapping enabled the team to have a comprehensive view of the tasks, processes, and roles which could be compared to their current operating model. WP&C then used the estimated time requirements for existing, as well as new activities, to develop a data-driven resource allocation model to quantify headcount for the new roles. The model considered factors such administrative burden, training, and over time, as well expected efficiency gains that would come from the specialized roles. After modeling headcount for each role, team size and supervisory span of control guidelines were used to shape the overall organization.

WP&C reviewed and fine-tuned the model with key members of the client leadership team to stress test the results and identify potential areas of risk. Leadership reviews resulted in minor adjustments to the model to mitigate identified risks through addition of small resource cushions for the most critical supply chain activities.

To right-size the future organization, WP&C recommended the following:

- Develop a holistic, detailed understanding of required activities and resources required to execute the current tasks of the supply chain organization

- Develop detailed linkages between current and future state roles to ensure there are no “dropped balls” during the transition

- Develop a resourcing model based on real world task performance data and projected efficiencies for optimized business processes

- Identify where under-resourcing would pose the greatest risk to future operations and integrate resource cushions where appropriate

- Involve key client stakeholders in the process to ensure leadership and organizational support for the resource plan

- Conduct a definitive review 90 to 180 days after implementation to evaluate task loading for the new roles and adjust resource allocations as needed