With the rapid technological change in the past 20 years, a US military organization had adopted the latest data management systems. However, the leadership was unable to leverage the systems at full capability and use data to make informed decisions due to issues with poor data quality and unclear responsibilities for improving and sustaining data accuracy.

The commonly used supply chain data were stored in different ERP (Enterprise Resource Planning) platforms. Although an integration hub was in place to consolidate and synchronize data from these ERP platforms, the employees found many inconsistent and missing data across the systems.

Moreover, standard processes to resolve data issues across the organization did not exist. For example, people did not know who was responsible for correcting the data when issues were discovered. Without clear guidelines or standards for data management, the issues remained unsolved. Poor data quality and unclear accountability hampered data analytics capabilities and therefore slowed decision making and overall organizational agility.

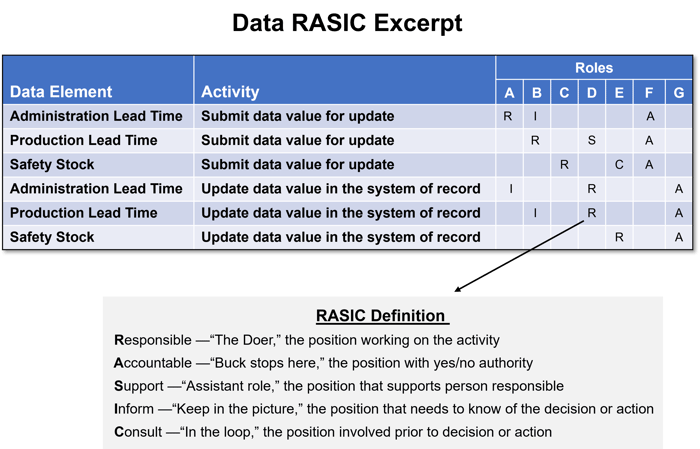

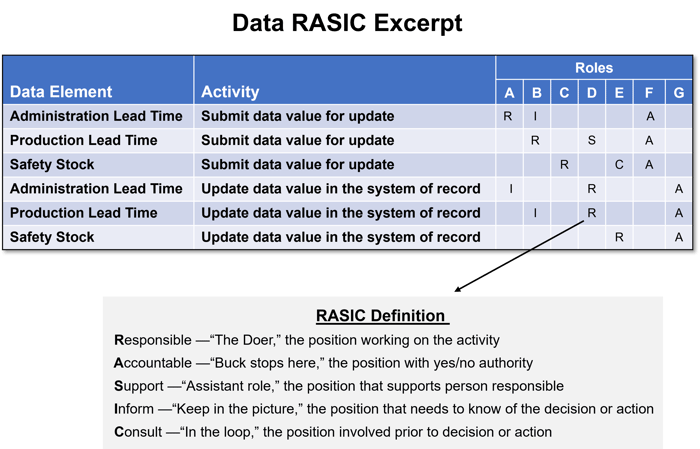

WP&C assessed current data quality issues and the current supply chain data management efforts, including available tools and data element maps, and interviewed subject matter experts from the data analysis, master data, and database management teams. Based on the assessment results, we developed the scope of the supply chain data management strategy, built a standard process for resolving the data quality issues, and established new policies and business rules for supply chain data management. We also developed a Data RASIC to define responsibilities for managing specific data and a Data Dictionary to establish common definitions for key data fields.

For each supply chain data element, the Data RASIC designated key data management tasks to roles that need to be involved. The responsibilities were assigned to roles best positioned to collect and update the information. A data dictionary helped employees understand the definition of data elements listed in the Data RASIC.

To develop the Data RASIC, several workshops were held with a cross-functional team to assign the accountability of each data element to the role best positioned to determine and update the values. In addition, WP&C analyzed existing data and worked with key stakeholders to ensure data elements enabled business rule and process execution.

WP&C developed a supply chain data management strategy to improve data quality and clarify data management accountability. Several tools were developed and implemented:

- Implemented Data RASIC to assign accountability for data management activities of each key supply chain data element, including determining correct data value and updating the data element

- Created Data Dictionary as a library of supply chain data element definitions

- Established supply chain data management policies and business rules to ensure guidelines and standards were in place to govern ongoing data management activities

- Developed Data Management Training and prepared trainers to help employees understand the new documents and their new responsibilities in managing supply chain data

- Performed a preliminary data review and clean-up according to the new policies on a few key data elements to improve data quality for effective automatic order releases

The new supply chain data management strategy allowed the client to become more data-driven and enabled more automation in operations:

- Data RASIC was adopted by over 1,500 employees in supply chain management and frequently used in leadership meetings and staff training

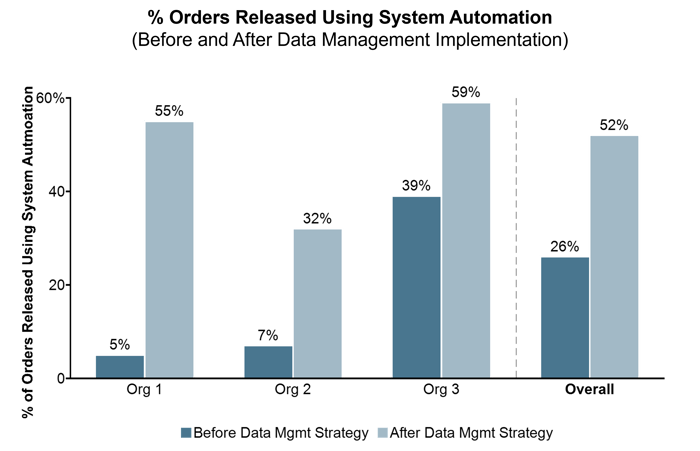

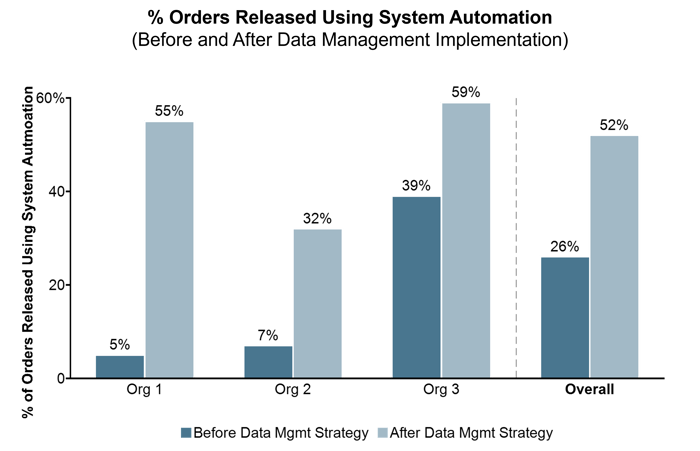

- Within 60 days of the initial data clean-up, the overall percentage of orders released through system automation vs manual review increased from 26% to 52% (an 11x improvement for one organization); this efficiency gain would have been impossible without the improvement in data quality and management