The headquarters of a large global logistics enterprise sought to restructure and standardize its outdated supply chain operating model. To be successful, the effort required extensive design input and buy-in from experts and leaders of three subsidiaries that had operated for many decades with relative independence.

This organization also had a long history of struggling to drive collaboration among the subsidiaries as their cultures and operating styles varied widely. The extent of operational independence was evident in their use of different definitions for common technical terms and very different approaches to executing common supply chain processes. These challenges made communications between the subsidiaries difficult and served as a strong barrier to collaboration. Moreover, the enterprise’s historic use of “working groups” for cross-organizational and/or cross-functional projects was generally unsuccessful. These groups were viewed very skeptically by leaders, and therefore they tended to lack the energy and focus needed to produce meaningful results.

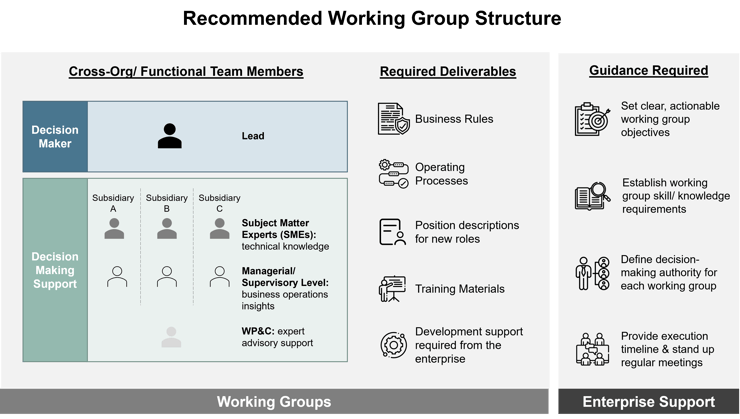

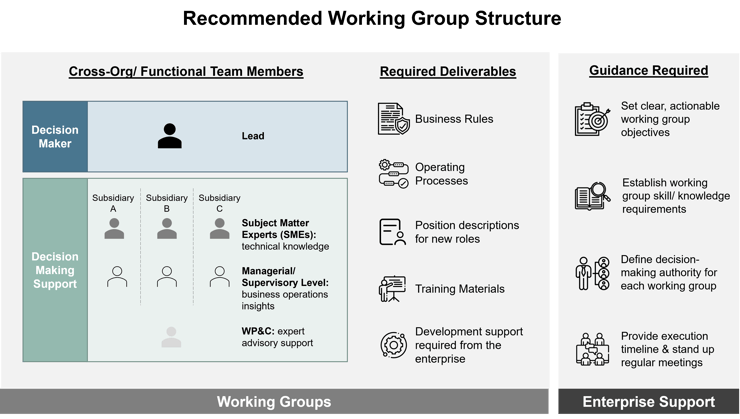

WP&C worked with client leadership to structure the working groups to address these challenges head-on. First, using WP&C’s extensive experience developing high-performing organizations, we defined the key criteria for cross-organizational/functional teams to be successful. Using these criteria, we worked with enterprise- and subsidiary-level leadership to develop charters which clearly laid out each group’s objectives, decision-making authority, skill/knowledge requirements, and execution timelines. Taking this approach clarified the scope of effort and responsibility for each group, their decision-making authority for final recommendations, and informed the staffing decisions for SMEs.

While these structural considerations were important, working groups were ultimately successful due to High Reliability Organization (HRO) operating norms, including forceful working team back up, a strong questioning attitude to scrutinize the work of others, and a deliberate focus on formality to ensure decisions and recommendations were well documented and ready for implementation in the broader design.

WP&C played a critical partnering role to develop the working teams, continually coach team members in the exercise of their decision authority, and ensure that all of the teams remained focused on the main objective of the operating design. Finally, the organization’s senior leaders respected the decision making that had been delegated to the working teams while providing appropriate oversight to ensure the working teams’ decisions and recommendations were adequately stress tested before final adoption.

To maximize cross-functional and cross-organization teams’ effectiveness:

- Establish clear, actionable objectives for the working groups and define the delivery date(s), including clear definitions of commonly used terms and concepts

- Define the subject matter expertise required for the team and identify individuals with strong track records and required expertise to participate

- Define the decision-making authority for the group (as it relates to the group’s objectives and internally for the team’s work, especially when the team members were unable to reach a consensus on key decisions)

- Have the working groups provide regular progress updates to enable Senior Leader decisions on key recommendations and escalate issues that put the deliverable timeline at risk

- Adopt and practice HRO principles and operating norms within working groups