Poor execution will very quickly sink an oil company; established players understand this and have spent decades refining the processes & procedures they use to manage their business to ensure they are executing well. The company, a relatively new player built around innovative oil-extraction technology, entered the market in the last decade and recognized the need to employ an Operational Excellence Management System (OEMS) to standardize processes to drive safe, reliable, efficient performance of its assets. Risk identification, risk mitigation, hiring & training employees, and change management are critical processes in high-risk, asset-intensive industries like oil & gas. The company’s initial OEMS was a collection of what it saw as the best components of the management systems of established industry leaders. But in doing so the resulting management system was made up of elements that were not mutually exclusive and collectively exhaustive, a combination of objectives & sources of risk, and inconsistent in formatting/style. This severely hindered adoption, use, and effectiveness.

After 2 years of significant investment and effort with little progress towards adoption and no improvement in performance, the company looked to WP&C with our deep expertise and experience designing and implementing OEMSs to review their current OEMS and make recommendations for a path forward. The work included three primary focus areas:

- OEMS Assessment & Redesign: The objective of the first phase of work was to assess the current OEMS for adequacy and suitability. This involved a deep-dive review of existing management system documentation at the corporate level and operating assets, then comparing the current OEMS with our WP&C 7-Element Operational Excellence Management System. Based on the findings of this work and consultation with the company’s operational leadership, we determined that a full-scale redesign was necessary.

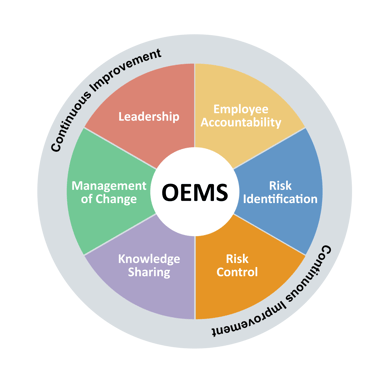

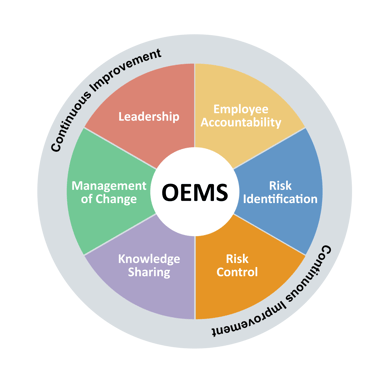

- Documentation of Key Processes: With a new OEMS structure in place based on the WP&C 7-Element OEMS, we worked very closely with the company’s SMEs to write the OEMS standards that defined key processes around Leadership, Employee Accountability, Risk ID, Risk Control, Knowledge Sharing, Management of Change, and Continuous Improvement to ensure that these standards were fit-for-purpose and appropriate for the organization’s needs.

- Roll-out & Implementation: Working with corporate and asset operational leaders, we developed an implementation plan based on building a deep understanding of what is required by the OEMS, why it is required, and how it will drive better performance.

After the initial assessment phase, our recommendation to the company’s operations leadership team was to start over with a completely new OEMS—the challenges, frustration, and lack of clear benefit associated with the roll-out of the previous OEMS, along with its inconsistent design, the organization would be more open to a brand new OEMS over a modification of the existing OEMS.

- New OEMS: With slight modifications to make the language, structure, and approach suitable for the organization, the company’s BOD adopted the WP&C OEMS as the Operational Management Systems (COMS) that they would use as the framework for driving safe, reliable operations at all of its assets.

- Standard Development & Implementation: The previous incarnation of the OEMS was built at the corporate level and then handed over to the operating teams at the assets. Our recommendation to ensure quality, fit-for-purpose, and adoption/ownership of the OEMS was to involve SMEs from corporate & the assets along with asset leadership in the development of standards and the implementation plan.

In less than 12 months, the company was able to develop its new, simplified OEMS, develop the supporting standards & tools, and provide training to key employees responsible for implementation of the revised OEMS at all of its oil-producing assets. The work WP&C did with the company to redesign and implement a new OEMS took less than half the time, required far fewer resources, and resulted in much faster and more complete adoption than the previous effort. In fact, the corporate team responsible for managing the OEMS shrunk by more than 80% and there are no dedicated OEMS team members at the assets. Instead, the OEMS has become part of how everyone works and has led to progressively better safety, environmental, compliance, and efficiency performance.