So how do you resolve the shortcomings of traditional approaches to Operational Excellence? What is the “better approach” we’ve been touting?

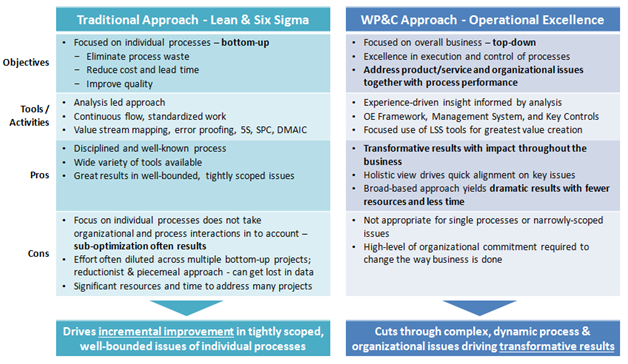

Let’s recap what we have covered so far. Traditional approaches to Operational Excellence have failed to deliver the expected results. Despite conventional wisdom, they haven’t failed because of a lack of commitment on the part of executives. Rather, they have failed to account for growing complexity and the Vicious Complexity Cycle. We highlighted 4 reasons that traditional approaches are ill equipped for addressing complexity.

- They start with an inadequate definition of OE

- They use a bottom-up approach

- They take a narrow view, failing to address the interactions between processes

- They try to improve processes before gaining control of them

We have provided a better definition of Operational Excellence that establishes clear and measurable objectives so an organization knows where it is going and what success looks like.

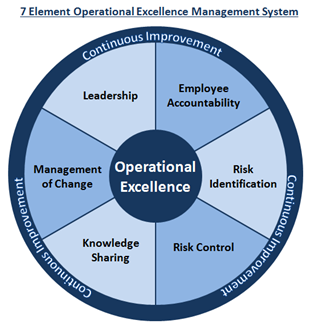

Having established what needs to be achieved, the next step is to address the other three mistakes traditional approaches make in trying to achieve Operational Excellence. The 7 Element Operational Excellence Management System (OEMS) we developed does just that – it is a top-down approach that addresses the interactions between processes and seeks to gain control before moving on to process improvement.

What we are suggesting is NOT installation of what many people think of as a traditional management system -ISO standards, PSM, or any of the other management systems companies typically use to establish and manage standards/procedures. While the OEMS does provide a framework for accomplishing those objectives, it is a fundamentally different approach. It is a mental model, a way of thinking about the elements essential for executing any process at the highest level. It provides an enterprise-wide framework for systematically installing and managing the key controls necessary to manage risk and deliver Operational Excellence. It is the approach that is necessary for today’s complex world.